[Story of Amber #5] The Chameleon Effect: How Amber Mill is Raising the Bar for Lithium Disilicate

- Date : 2022.06.14

The Chameleon Effect: How Amber Mill is Raising the Bar for Lithium Disilicate

Keith Morgan is founder and director of Digital Dental Laboratory Toothworx and a proud UK

Ambassador for Amber Mill lithium disilicate, available from DB Lab Supplies. Here, he talks

about why he chooses Amber Mill lithium disilicate, and how suggesting Amber to clients has resulted in repeat requests.

Based in Cardiff, Toothworx is a crown and bridge lab offering the full-spectrum of services; from bespoke single

unit restorations, to more specialist full contour implant retained work. It also offers an in-lab bespoke shade taking service.

Keith became an Amber Ambassador in 2020, after being impressed with the product, and now

regularly shares his cases on his Instagram and Facebook pages @toothworx and @toothworx1.

He says of Amber Mill, “I’m now able to offer next day crowns for local customers with Amber Mill.

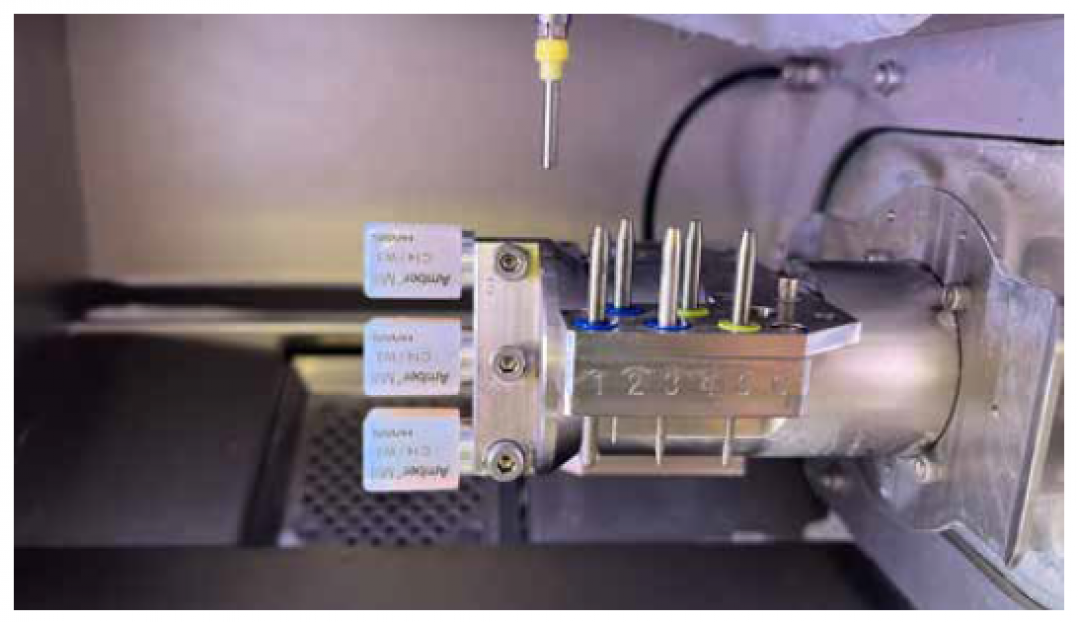

I use a wet mill DWX42W and Amber produces consistent results with minimal effort.

I use Amber Mill for veneers, crowns, onlays and inlays, monolithic or porcelain layered.

I began suggesting it to my clients on the basis that if they weren’t happy, I’d re-do the restoration at no extra cost in their usual product.

Every time it has worked brilliantly so clients go away happy having discovered a great alternative aesthetic product.

Plus, the feedback on onlays and inlays is fantastic. It has a chameleon effect; it is fitted in the tooth preparation and simply disappears.

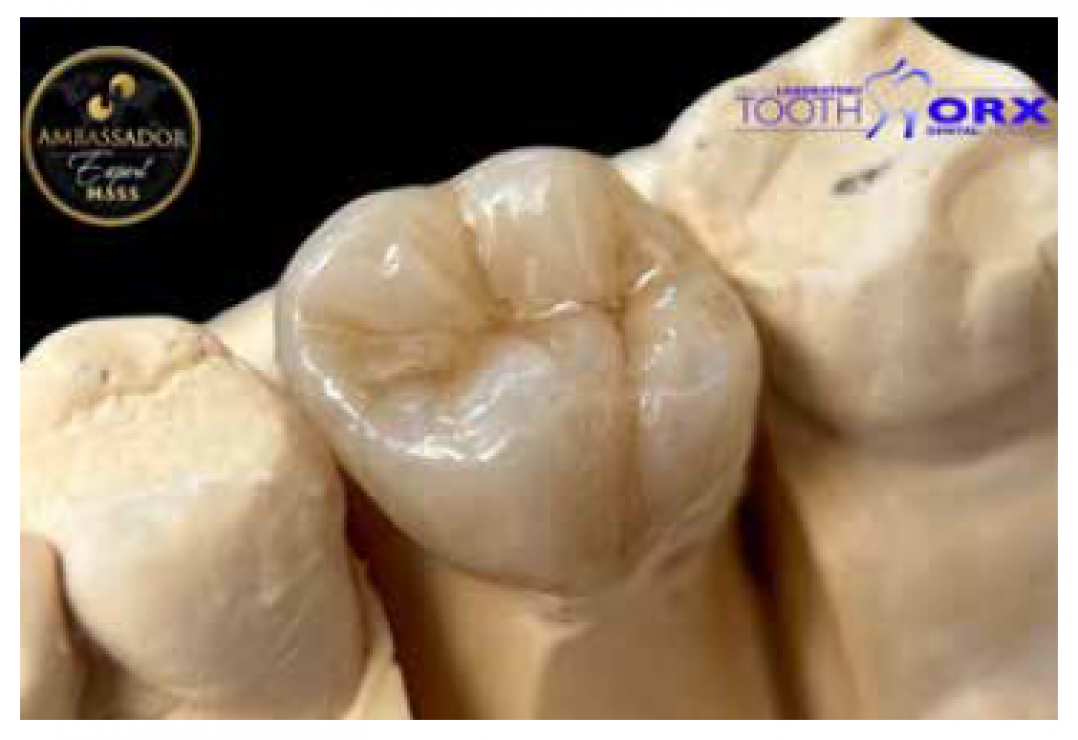

Images courtesy of Toothworx. L-R: Amber Mill Molar Crown finished with Miyo Liquid Ceramic,

Amber Mill 3/4 core layered with Emax Ceram Porcelain and Incisal Effects Following in lab Tooth Mapping.

Amber Mill: lithium disilicate for CAD / CAM milling

Amber Mill is available in blocks and blanks and is suitable for the fabrication of crowns, bridges, inlays onlays and veneers.

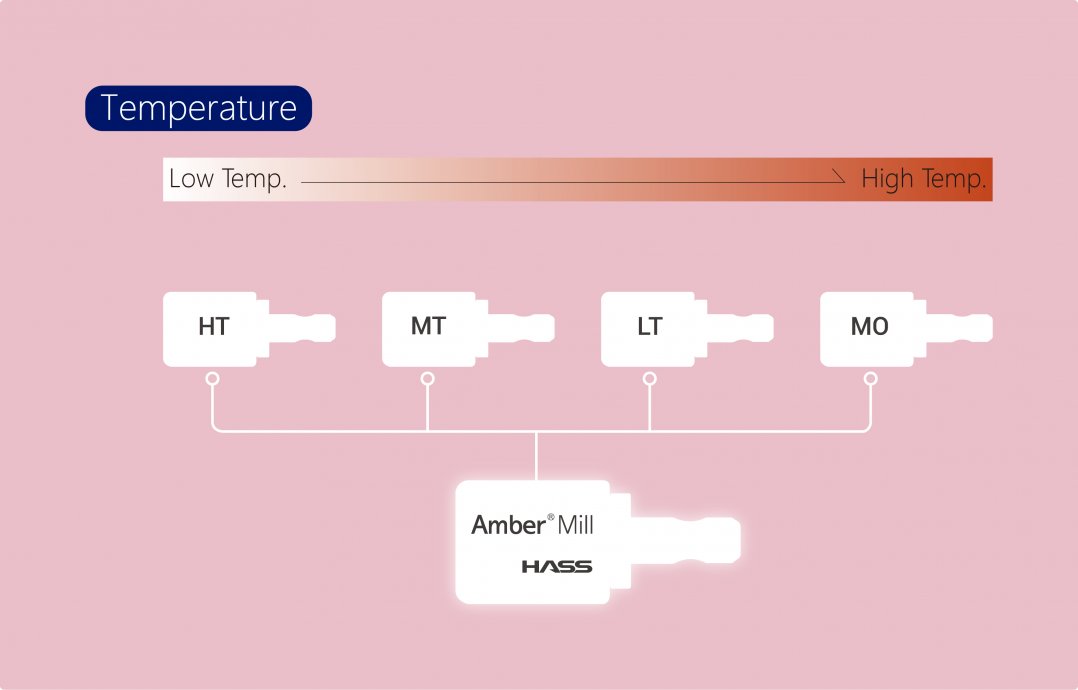

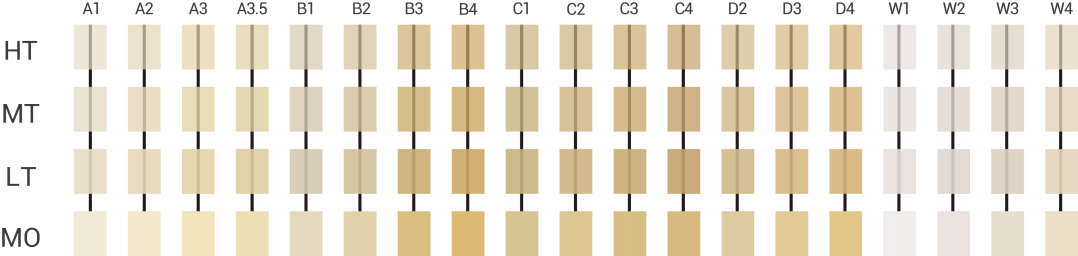

The nano- lithium disilicate technology (NLD) offers a range of advantages including the unique

ability to control translucency by adjusting the firing temperature - one ingot can produce four variations - HT, MT, LT and MO.

Simply select the translucency and the firing temperature determines this.

During the heat treatment, crystal size and density are increased and consequently the mechanical properties are reinforced and translucency value changed.

The higher the temperature when firing, the more opaque the restoration. Even after finalising, the translucency can

still be adjusted as the restoration can be re-fired from HTMT onwards.

The advantage of this is the ability to achieve a wide spectrum of light-optical properties with a quarter of the usual number of blanks required.

L-R: Produce 4 translucencies from one block. Shades available in Amber Mill.

Due to its natural-looking light-reflecting properties (remarkable opalescence and fluorescence), Amber Mill produces excellent aesthetics.

The biaxial flexural strength is 450 MPa after crystallisation, making restorations monolithic, and its strength in its milling state is 250MPa.

These properties enable high edge stability with more predictable mills and no chipping. Amber Mill is also compatible with the majority of veneering ceramics.

“The feedback on onlays and inlays from Amber Mill is fantastic.

It has a chameleon effect; It is fitted in the tooth preparation and simply disappears.”

Amber Mill on wet mill DWX42W. Images courtesy of Toothworx.

No chipping

Keith says, “I can cut it really thin and it will not chip.

It is advised to mill to no less than .8 mmm, yet I’m milling to .2mm; creating a fine knife edge finish that still will not chip.

I’ve also produced between 50-60 veneers in bleach shades; giving that Hollywood smile. Also, the reduced inventory is a massive plus point.

I buy one product and it covers all translucencies - dependent on what is desired for each case.

Producing four translucencies from one block adds a freedom; I can go back and forth with the firing.“

“I really like the material. It offers great versatility and consistent, highly aesthetic restorations - the ideal product”

No cutting corners

Keith’s extensive CAD/CAM experience, and passion for aesthetics and customer service has gained him glowing testimonials.

He says, “I only offer the best products and I never cut corners.

I am so passionate about offering the highest aesthetics and this is why customers will give my suggestions a go.

The business is still growing, leading to new team members joining us and a steadily growing client base.”

Get in touch

To find out more about Amber Mill, call DB Lab Supplies team today on 01535 656999, email the team on

sales@dbortho.com or contact Toothworx Dental Laboratory on 02921321065.

*source : https://www.dblabsupplies.co.uk/